One of the most significant developments in the printing industry this century is the way it addresses its impact on the environment. The sector is constantly introducing new materials and processes to support sustainability and to ensure that we do our bit to help the planet.

As a customer you have the power to make a difference too. By choosing a print partner that’s aware of its effect on the planet and selecting eco-friendly products from their range, you send the message that green business is good business. Look out for companies that employ eco-friendly methods of printing by using renewable energy, eco-friendly inks and sustainable materials. You can continue to make a difference when selecting your print. By picking recycled, Forest Stewardship Council® (FSC®) certified, or carbon offset materials, you Reduce your environmental impact and demonstrate your eco-credentials.

What are eco-friendly paper options?

Environmentally friendly paper options include recycled paper, FSC® certified paper and carbon offset paper. But what does this mean?

What is recycled paper?

Recycled paper is made from post-consumer waste, reducing the need for new wood pulp. This allows for a significant reduction in the amounts of energy and water consumed compared to virgin paper manufacturing. By using old paper, recycling reduces the volume of paper sent to landfill and cuts pollution associated with waste disposal.

What is FSC® certified paper?

FSC® certified paper is sustainably sourced from forests managed with environmental and social benefits that meet the rigorous standards set by the Forest Stewardship Council®. FSC® standards for forest management extend to safeguarding water quality, preventing the loss of natural forests, stopping the harvesting of protected forests and ending the use of hazardous chemicals that pollute water sources and have been proven to cause birth defects.

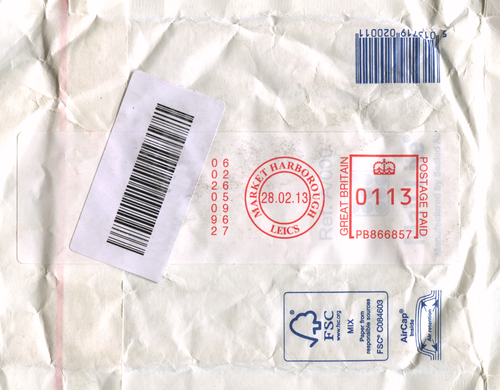

FSC® is a huge organisation which works hard to ensure we can have safe and sustainable printing resources. When you order print on FSC® certified products from Solopress, you have the option of displaying the FSC® logo. Whenever this logo appears on print, it displays a unique licence code representing the printing company. This allows for the material to be tracked back to its source. It also notifies recipients whether the product is made from fully recycled or mixed materials, as well as demonstrating your commitment to responsible procurement.

What is the difference between FSC® mixed and FSC® recycled?

While FSC® mixed is not wholly recycled, it originates from 100% sustainable sources. FSC® certified mixed paper is made up of a combination of materials from certified forests, recycled materials and/or FSC® controlled wood. This means that this paper stock is made from a mix of materials all responsible sourced and certified by FSC®.

“Recycled” is a promise that the paper is made entirely from post-consumer waste materials, which typically uses 40-60% less energy than producing paper from virgin materials.

What is Carbon offset paper?

When a paper is described as carbon offset, it means the carbon emissions released during its manufacture have been balanced by funding projects that reduce or capture an equivalent amount of CO₂ elsewhere. The paper itself is made in the same way as standard paper, but its environmental impact is addressed after production through these offset contributions.

This process often supports initiatives such as reforestation, forest protection or renewable energy projects that help to absorb or prevent carbon emissions. In this way, the overall climate impact of the paper’s production can be considered neutral.

Solopress is proud to work with Climate Partner, an environmental organisation that helps us measure our carbon footprint and track carbon emitted resulting from production of specific products. For most of our bestselling products, we offer an option at checkout for customers to make their order carbon neutral. All funds go directly into Climate Partner’s carbon capture projects that offset emissions and reduce atmospheric CO2, as well as benefitting disadvantaged communities.

How is water recycled in paper production?

Water is a key component in paper manufacturing. While high water usage is often seen as concern, the industry is developing ways to use less of it, and to return it to the natural environment in a purer state. As outlined in a recent article in Chemistry World, mills are evolving and becoming cleaner and more efficient. Water is only returned to waterways if it is cleaner than when it was originally sourced. If it doesn’t meet these standards, another use for the water is found.

In addition, the industry is taking measures to use biological rather than chemical processes to remove contaminants from recovered pulp and to prepare it for production. Biomethane, a natural by-product of the process, can even be captured and sold to the national gas network as fuel!

How is paper filling a plastic gap?

As we turn away from plastics, especially those intended for single or short-term use, paper and card solutions are stepping up to fill the gap. By replacing plastic products with paper alternatives, we can reduce the amount of plastic waste in landfill, oceans and food resources.

A British company called James Cropper has even developed a process to fully recycled paper coffee cups. This process allows the plastic inner layer to be separated from the paper outer. This process allows the paper to be fully recycled and the plastic to be turned onto to pellets for future use. Developments like these are helping make paper a viable alternative to single-use plastics.

What is eco-friendly ink?

Eco-friendly inks offer a more sustainable alternative to traditional petroleum-based inks. Instead of being derived from crude oil, they’re made from renewable sources such as soy, plants and algae. Not only are they more responsibly sourced, they’re also formulated with their full lifecycle in mind. During paper recycling, these inks can be more easily removed in the deinking process, helping the fibres to be reused in new paper products. If sent to landfill, vegetable-based inks biodegrade more safely than petroleum-based formulations, which can contain VOCs and heavy metals that leach into soil and groundwater.

As well as being environmentally friendly these inks also achieve accurate colour representation which is vivid through litho presses.

Here at Solopress we use a variety of inks including eco-friendly vegetable-based and UV inks. Solopress is proud to have been one of the first commercial printers to use vegetable-based inks for lithographic printing.

How do eco-friendly printers and make a difference?

Industrial printing presses inevitably consume a substantial amount of energy. However, if renewable energy is used it significantly reduces the pressure on the power grids, whilst also reducing the release of CO2 from burning fossil fuels. Seeking out a print partner that’s committed to renewable energy helps fight climate change by reducing greenhouse gas emissions.

Digital or litho: which is more eco-friendly?

Both digital and lithographic printing can be sustainable choices, the key is matching the method to the size of your print run. For shorter runs, digital printing is generally the most energy and cost-efficient option. With little or no setup required, the print-ready file is sent straight to the press, avoiding the waste and materials associated with plate making or press preparation.

For longer runs, typically over around 2,500 copies, lithographic (offset) printing becomes the more efficient choice. Although it involves creating metal plates and running large presses, once in motion these machines operate at exceptional speed and precision. They produce up to 18,000 B1 sheets per hour, which means energy use per sheet is very low.

When you order from a well-equipped printer such as Solopress, your job is automatically routed to the most efficient production method, whether that’s digital or litho, so you can be confident it’s being produced in the most responsible way.

What are some simple eco-friendly printing changes you can make?

A decision print buyers can make that affects their environmental footprint is how they choose to view their proof. Proofing is an essential step in ensuring print looks as intended, but the way artwork is approved can still influence the resources used to produce it.

How to pick the right proof

For most projects, a digital proof, such as a PDF viewed on screen, is the more efficient choice. It requires no materials or transport, saving paper, ink and energy. If you’re reordering a design that’s been printed successfully before, or working with established brand colours, a digital proof offers a reliable and resource-conscious way to check your artwork.

However, for longer runs or new projects where precise colour matching is critical, a printed (wet) proof can be worthwhile. Produced using the same press and methods as the final job, it provides an accurate preview that can prevent costly and wasteful reprints later on. Ultimately, the most responsible proof is the one that gives you confidence the first print run will turn out right.

Another way to easily help the environment is to opt for double sided print over single sided. By making sure that printing books, fliers and other products double sided over having additional pages is an easy way to be more eco-conscious. By doing this the amount of paper, and therefore energy, needed is significantly reduced.

Does the paper industry destroy forests?

No. In fact, the opposite is true where forestry is responsibly managed. Across Europe, almost all paper comes from trees grown as a renewable crop within carefully controlled forest ecosystems. These forests are harvested and replanted in continuous cycles, with older trees preserved and biodiversity actively protected through certification schemes such as FSC® and PEFC™.

According to We Love Print and Two Sides, European forest area has increased by more than 58,000 km² over the past 15 years, an area larger than Switzerland, and continues to grow by the equivalent of around 1,500 football pitches every day. This expansion is largely supported by demand for wood-based products. This includes paper and packaging, which give managed forests an economic value that helps ensure they are maintained and replanted rather than cleared for alternative land uses.

So rather than destroying forests, the paper industry helps to sustain and renew them. Modern forestry management ensures that every harvested tree is replaced, older woodland is conserved, and forests continue to act as one of Europe’s largest carbon sinks, absorbing more CO₂ than they emit while supporting rural economies and wildlife habitats.

How does print impact UK forests?

Far from depleting forests, the UK’s paper and forestry industries rely on a cycle of planting, management and harvesting that helps sustain woodland growth. According to Forest Research (the research agency of the Forestry Commission and Great Britain’s leading authority on forestry and tree-related research), the UK’s total woodland area reached 3.28 million hectares in March 2024 — an increase driven by the creation of over 20,000 hectares of new woodland in the previous year alone. Nearly half of this woodland (44%) is independently certified as sustainably managed.

This ongoing management has real economic value. The forestry sector employs around 21,000 people and contributes more than £3 billion in gross value added through forestry, sawmilling, panels and pulp and paper production. By giving forests an active economic role, managed logging creates an incentive to protect and expand woodland rather than clear it for other forms of development.

Responsible forestry therefore links conservation with commerce, ensuring that trees are treated as a renewable crop whose careful use funds their renewal.

Is print production actually bad for the environment?

Although print can be perceived negatively, it has some of the most positive impact in our lives. It contributes to culture and learning, which improves the quality of life we all enjoy. Modern techniques mean we can print responsibly using sustainable energy and properly sourced materials. Without the paper and timber industries, forests would likely be neglected or even destroyed meaning less carbon would be absorbed and stored. By choosing print, we actually make a positive impact on the planet.